The manufacturing plant conducts random endurance tests of finished products in order to check the quality of manufactured products. The testing lasts around a month. The testing includes controlling load allowances, load frequencies, number of load cycles and duration of testing. If the controlled parameters deviate from the allowances, the system stops and a message about the stoppage cause is issued to the operators.

Operators monitor load values and the number of operating hours worked in real time. All registered data are written into a data base; therefore, it is possible to check the progress of testing, generate and print a report at any time.

Equipment: PXI/cRIO controllers (measurements, parameter control), PC (operator’s panel, data base)

Result: The quality of conducted testing and measurement accuracy has improved; reliability of obtained testing data no longer causes any doubts. The issues regarding product defects have been eliminated (overload by testing staff, or manufacturers not following the technology), the end user can view a report on the conducted testing, the supplier’s reputation has improved.

The existing testing stands are partially automated. In the course of testing measured data are written into binary files, but since the system developer left the plant, viewing the contents of these files is impossible; besides, the format of the files is known only in general terms.

During experiments we found out the file format and created a program allowing to view the old data.

Result: Engine developers are capable of studying experimental data not only in the course of the testing stand operation, but at any other time. Moreover, the data are displayed in a convenient form: temperature fields with the capacity of automatically repeating testing patterns.

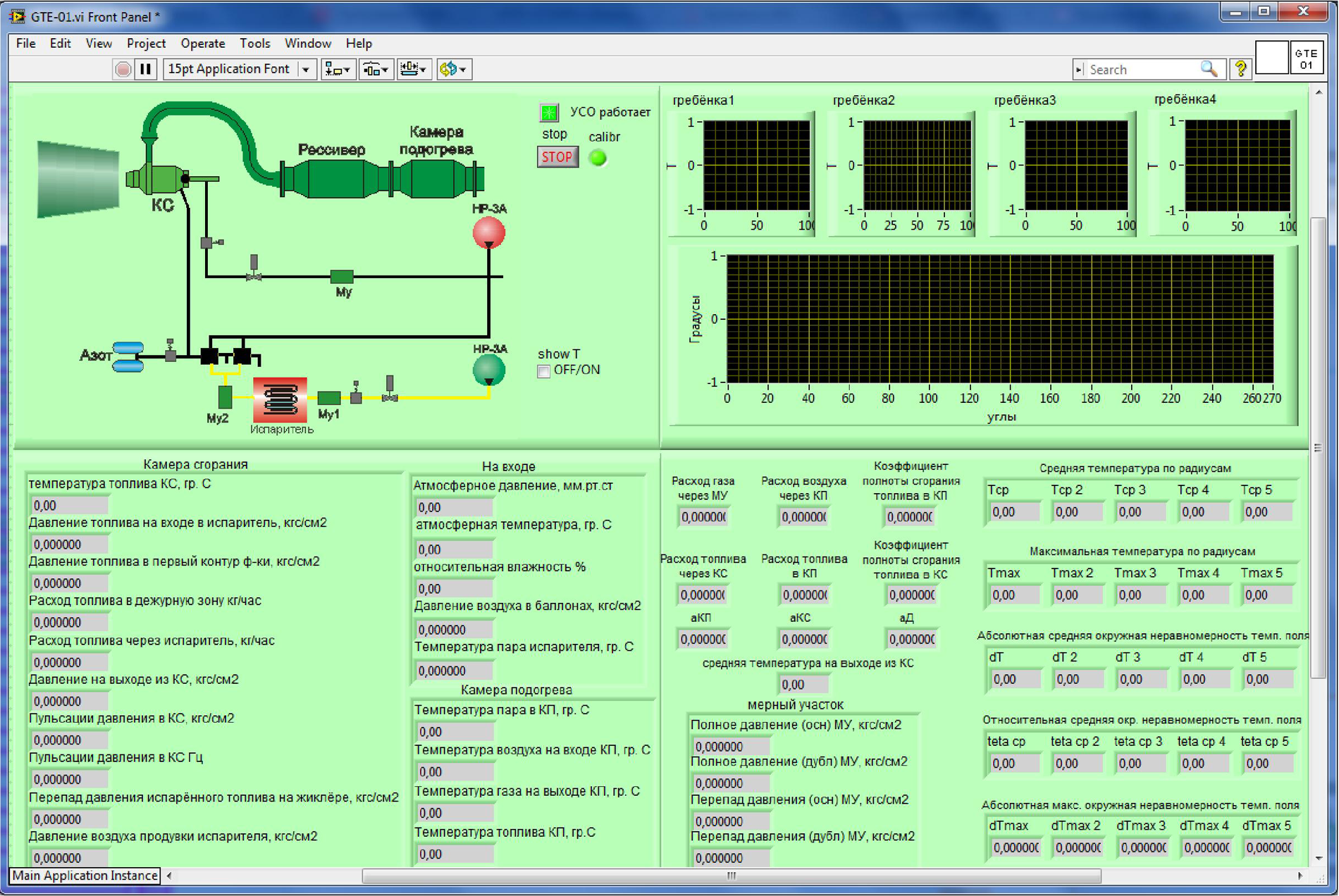

In the course of further upgrading of the testing stands, we developed a testing progress management program. The interface takes into account the requirements of the engine testing staff and engine developers. In terms of appearance, the control buttons resemble the equipment, which they control; therefore, even a beginner operator can easily learn to work with the program, and the measured information is displayed in the form convenient for the experimenter (as charts and circular diagrams).

The program uses the measurement equipment available at the stand.