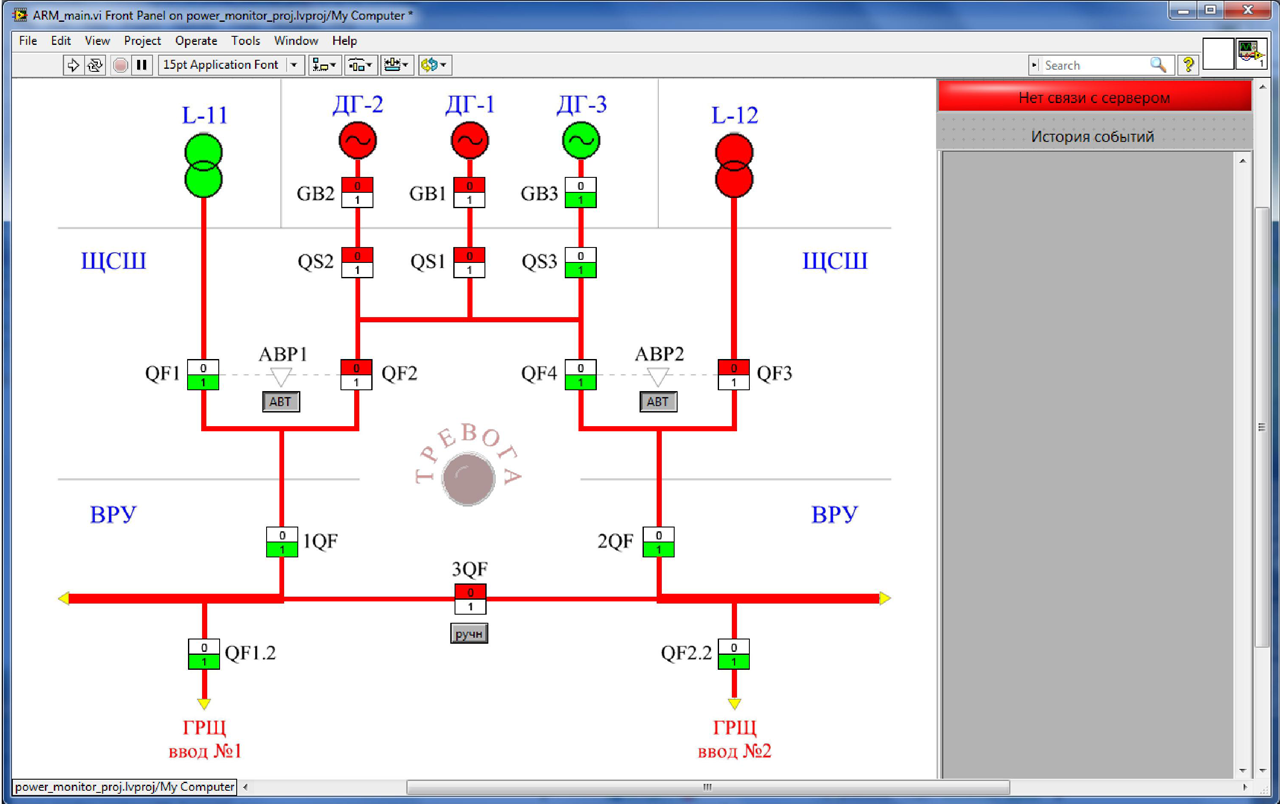

The program displays the condition of the center’s power supply lines in real time. An event log is kept.

Equipment: remote I/O modules by Moxa.

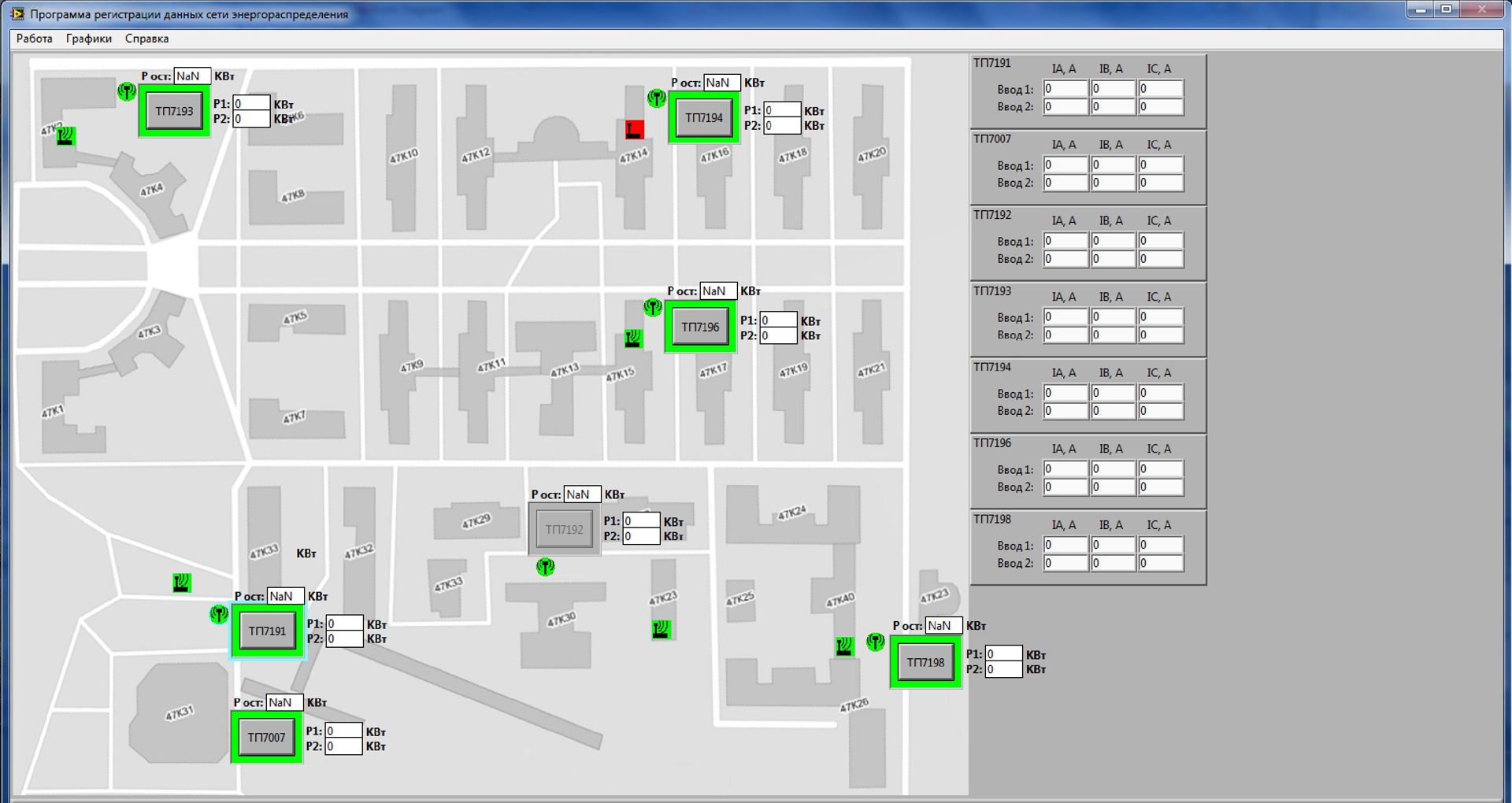

The system monitors the condition of power supply lines of the entire institute’s complex: condition of lines, loads, load and expenses accounting. Three levels of details are displayed on the screen.

First level: general plan of the complex with a layout of transformer substations. General condition of the elements is shown on the screen in color (whether connection is available, whether the loads are within tolerances).

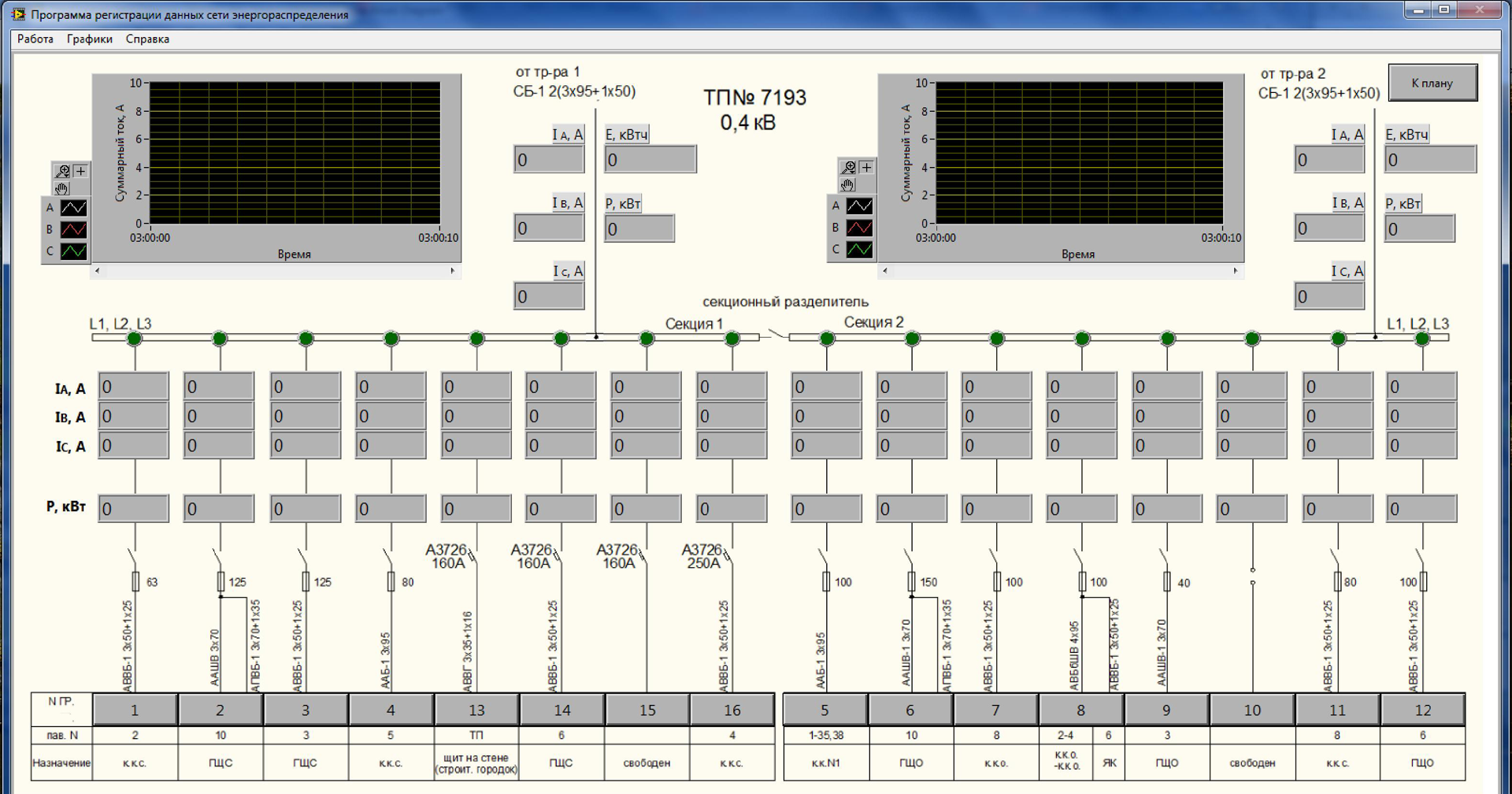

If necessary, using a push-button icon, the user opens a detailed image for the selected transformer substation where loads for each line are displayed.

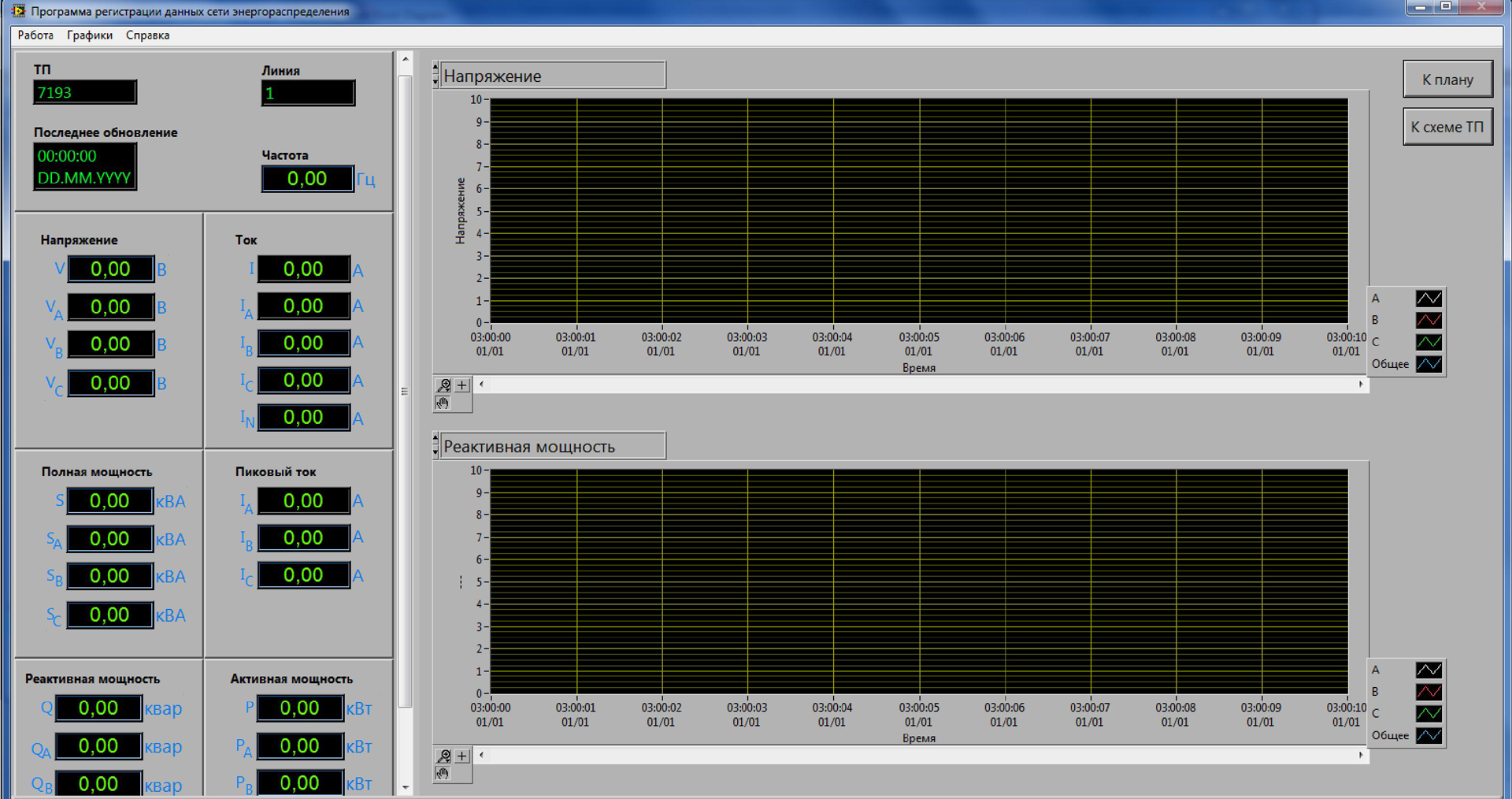

Then, by pressing the line’s button, the operator opens detailed information for this line. Not only current values, but also the trend for the selected period are displayed on the screen.

Equipment: remote I/O modules by Moxa.

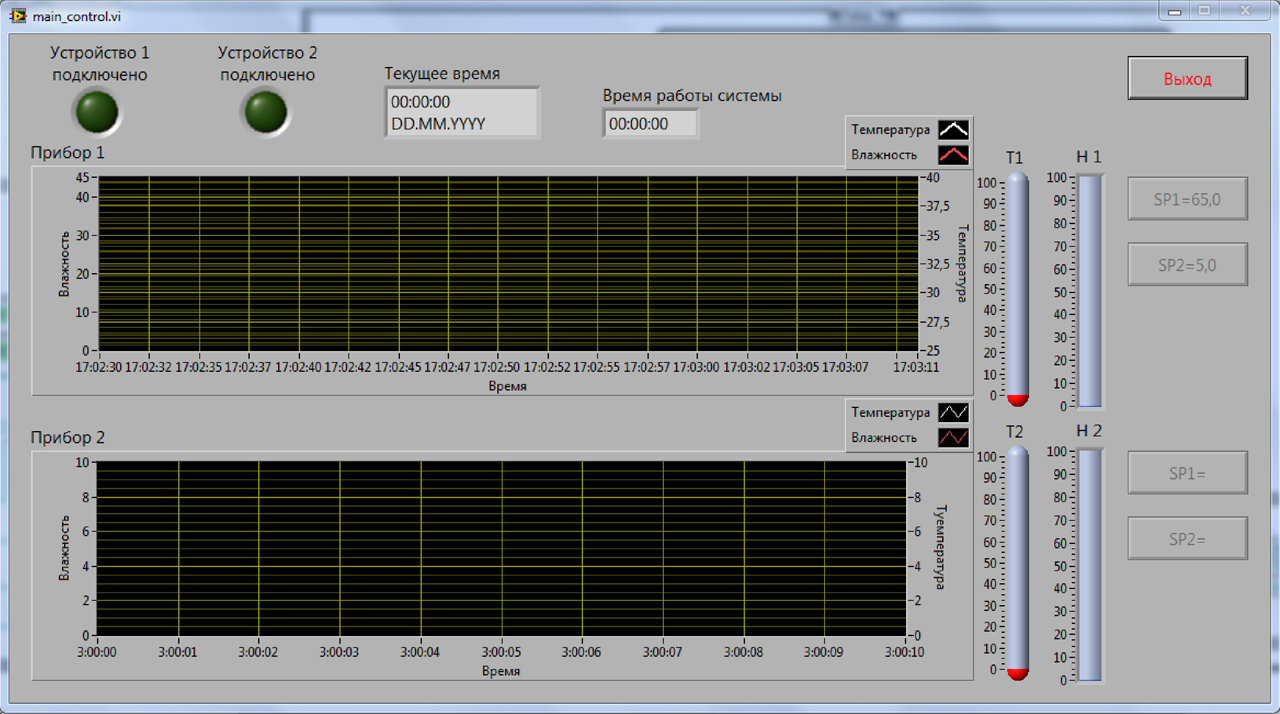

At the final stage of processing products are sent to the drying furnace. Drying is carried out automatically at night by an instrument by Oven, but the process engineer needs to know how the processes were passing in his absence. The program scans the instrument with pre-set periodicity and displays the data on a chart. The obtained information allowed to adjust the instrument settings and improve the quality of manufactured products.

Equipment: TPM10 controller (Oven)

In seismically active areas it is necessary to control the condition of buildings (residential houses), especially after earthquakes. Based on the appearance of a building it is not always possible to understand how severely it was damaged by the last shocks. At the same time this task is easily solved by measuring the structure’s natural vibration frequency. At the construction phase vibration sensors as well a controller registering necessary parameters (vibrations, calculation of natural frequencies, meteorological data) are installed in the building. The collected data are transmitted to the server of the Ministry of Emergency Situations, where the staff can check the condition of the structure in real time mode. At the same time the program itself analyzes the data, and when the values exceed the allowances, it informs the staff in charge about the upcoming danger.

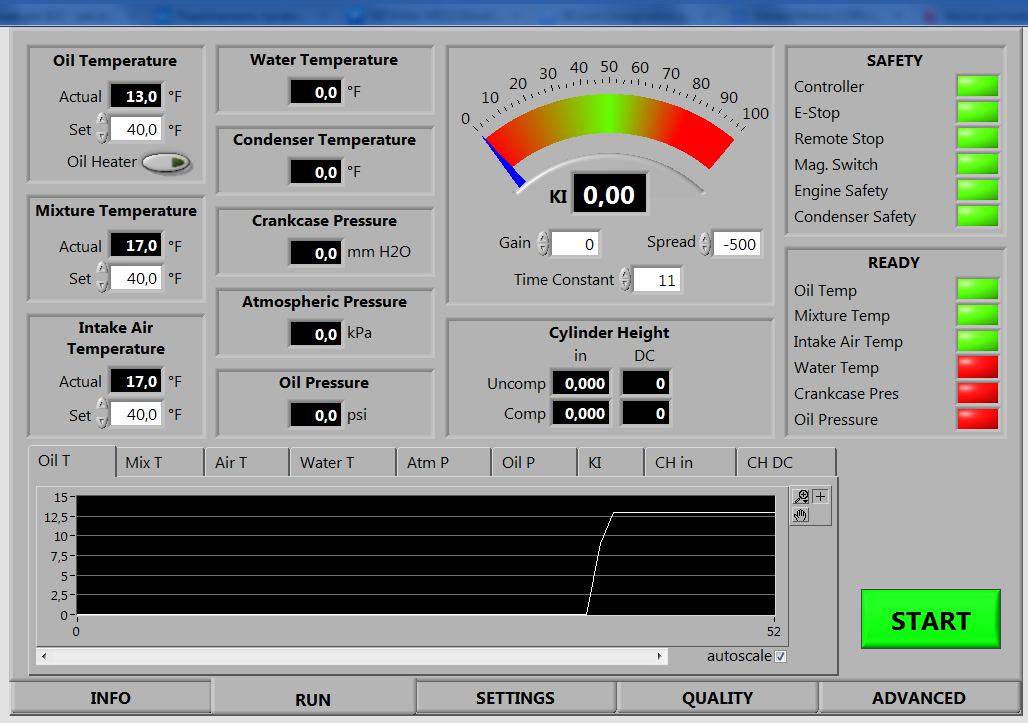

The unit used for determining octane numbers of petrol consists of a motor assembly and sensors. In the course of the motor’s operation it is necessary to control a number of parameters (if the parameters exceed the pre-set limits, the motor is stopped in an emergency mode) and calculate the values of the figures to be determined. Adjustment of temperature of fuel, air and mixture is carried out in the same way.

The main control of the system is performed by a cRIO controller (National Instruments).

The second part of software includes the user interface and works on any computer managed by Windows system. In addition to managing testing, the program allows to adjust testing parameters (temperature set-points, re-calculation coefficients, etc.); the settings can be changed only after entering a password.

The distinctive feature of the interface is the possibility to switch between Russian and English languages.

The system is operated at several oil refineries in Russia.

Equipment: a cRio controller with analogue and discreet I/O modules

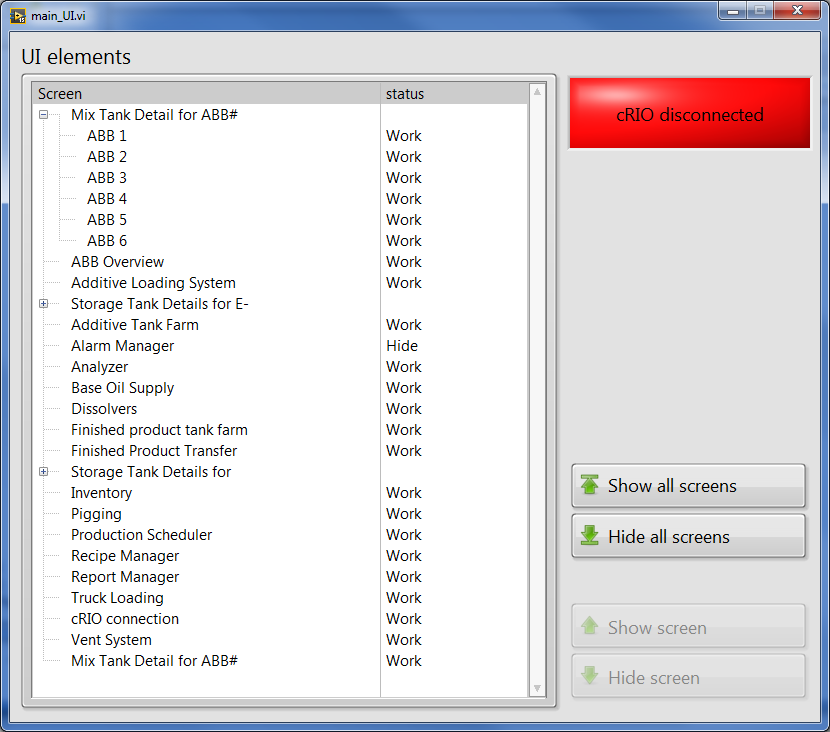

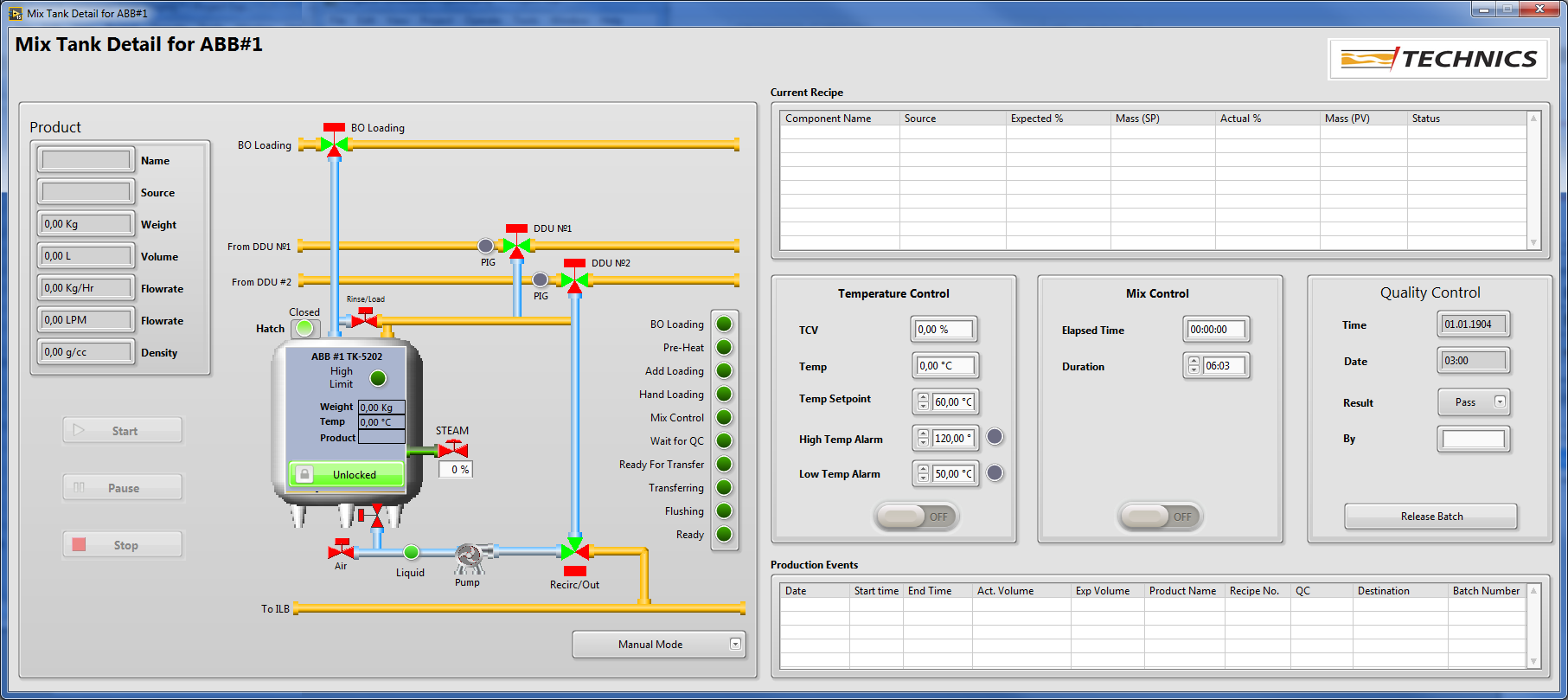

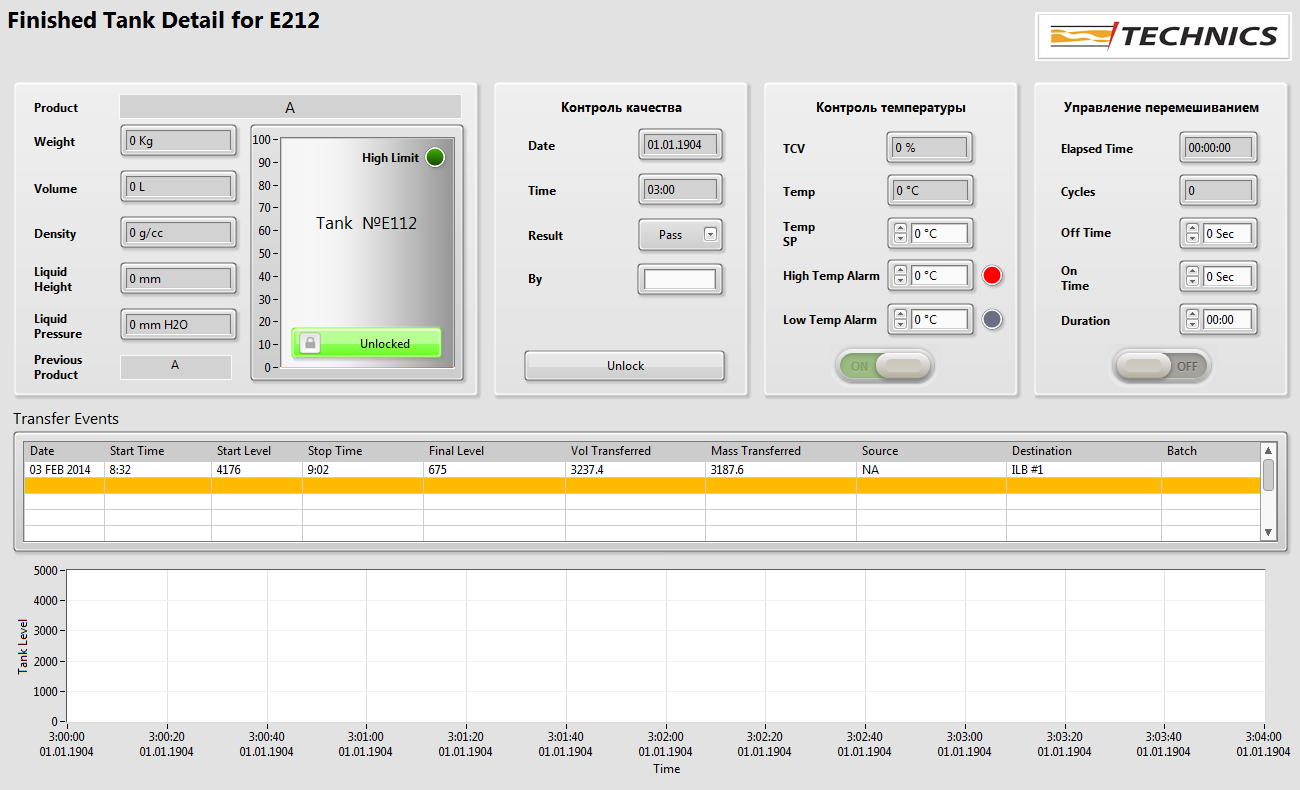

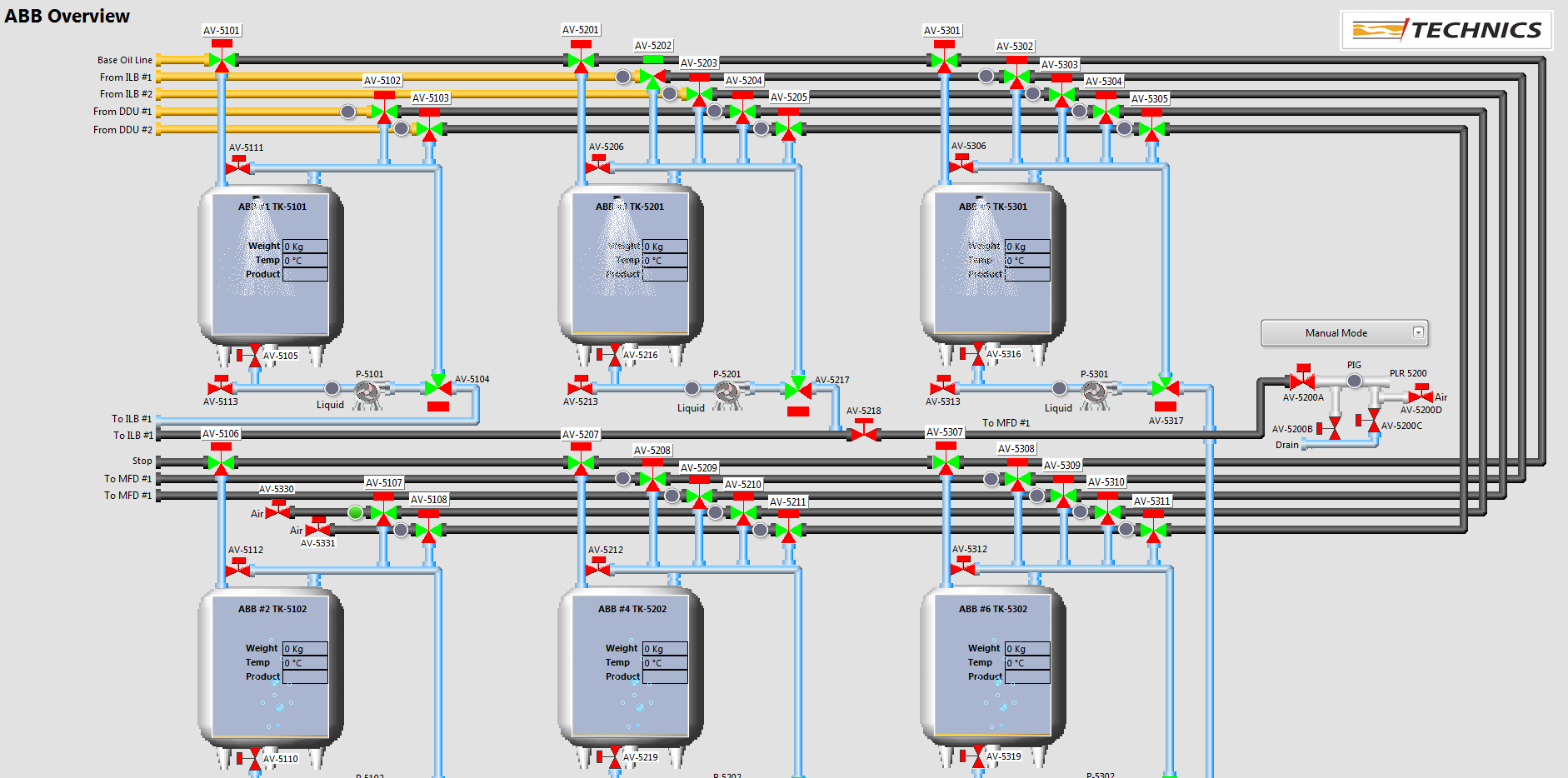

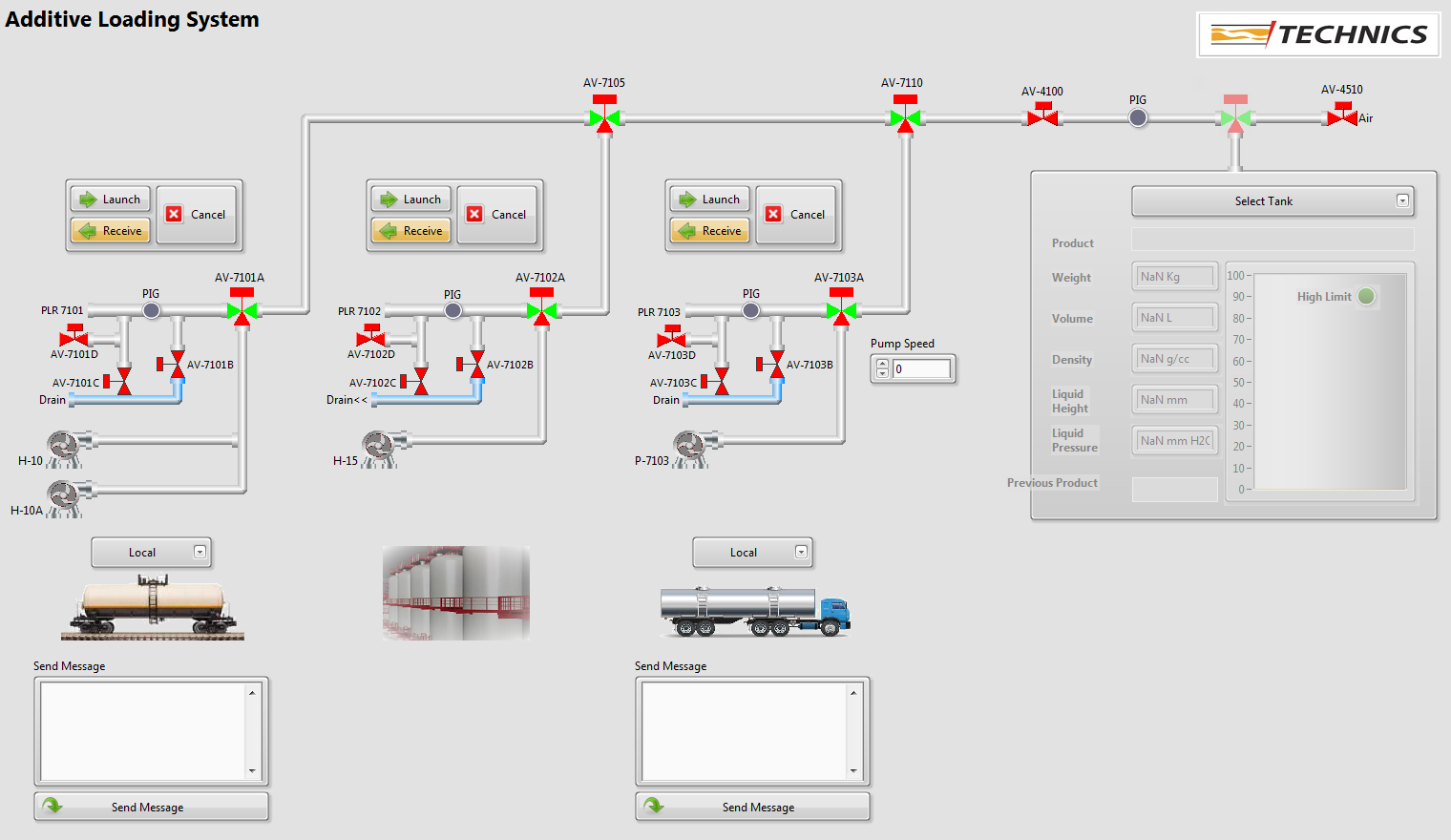

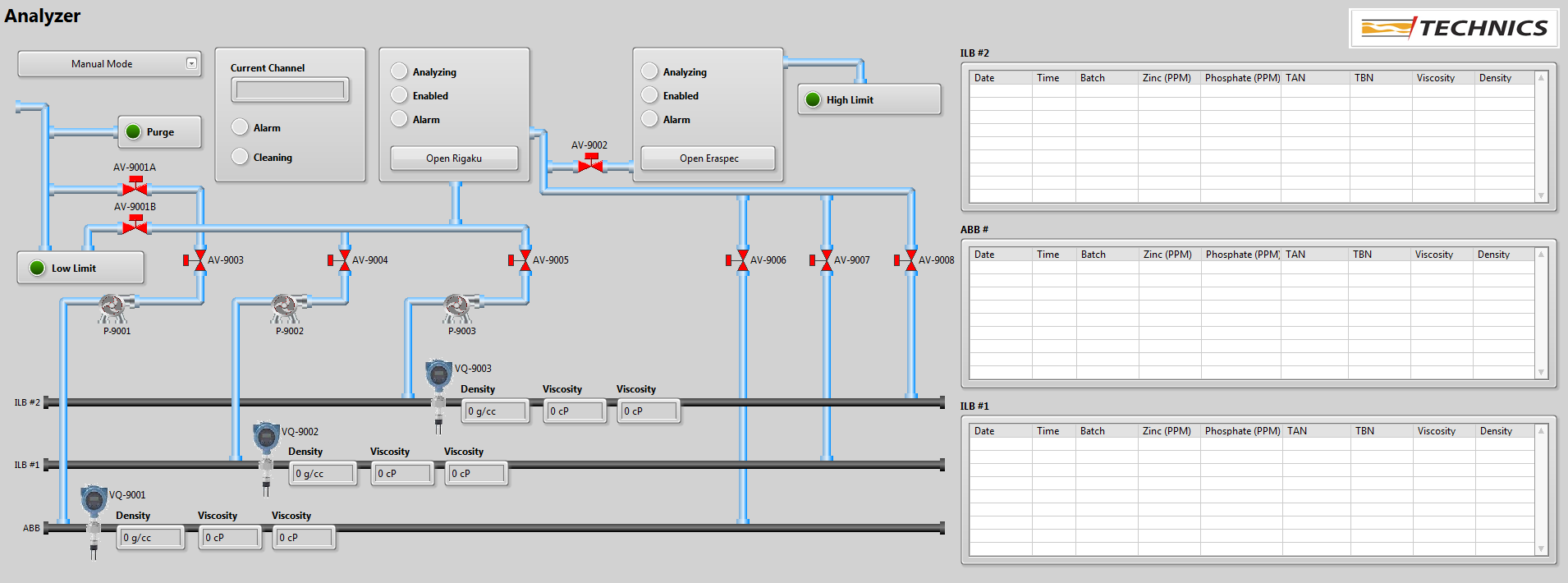

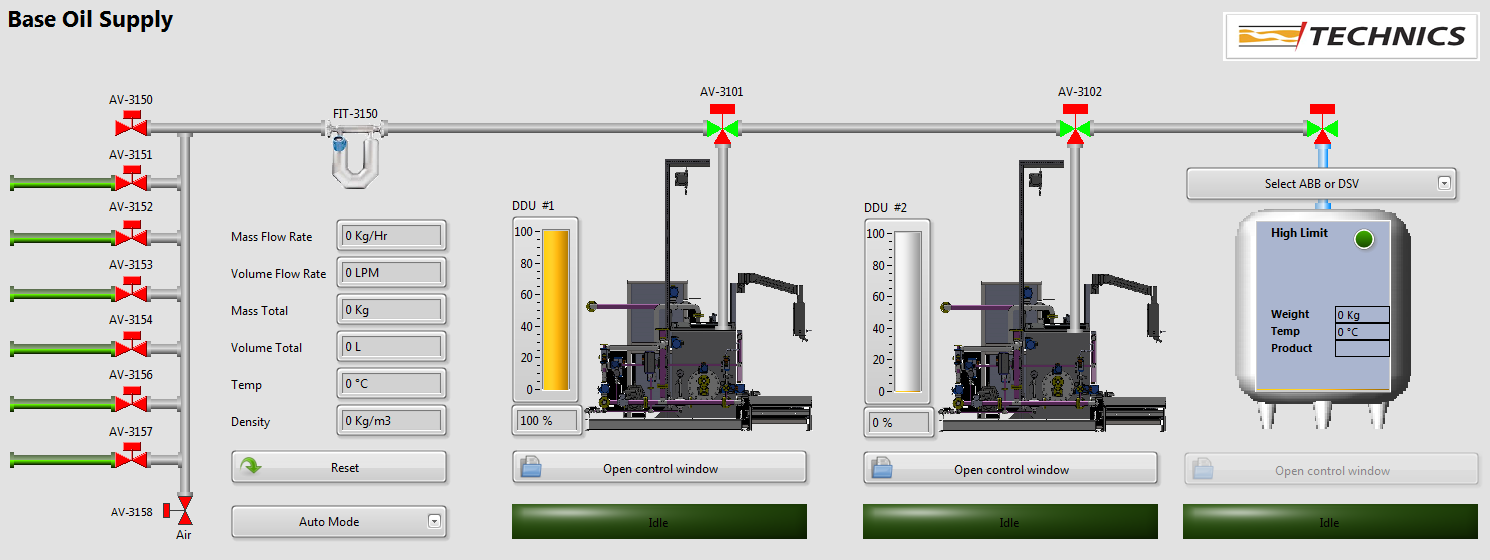

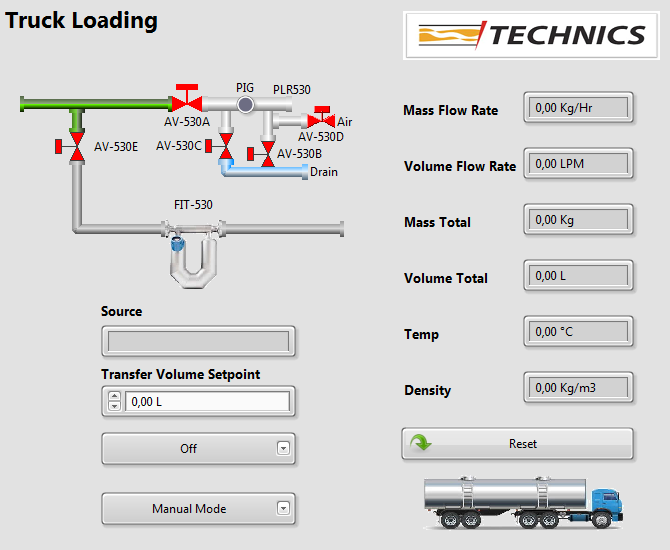

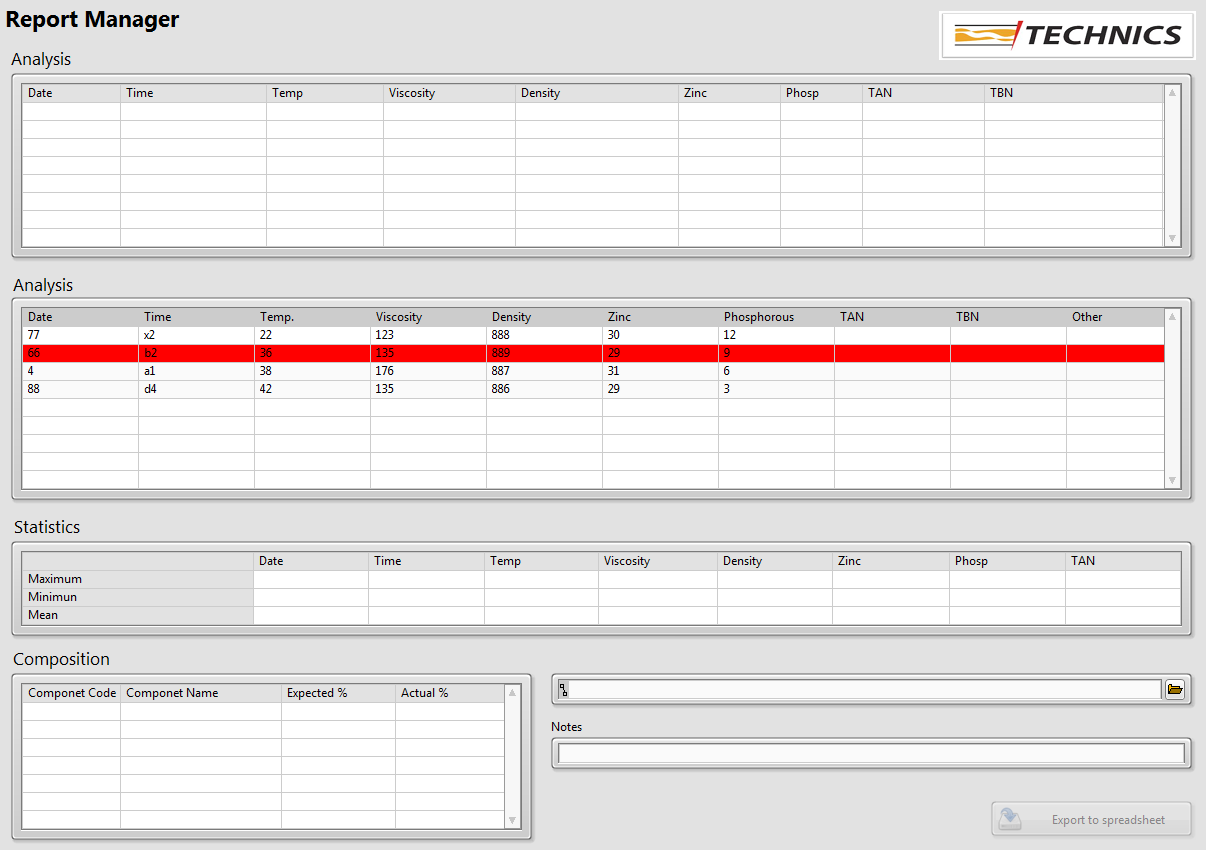

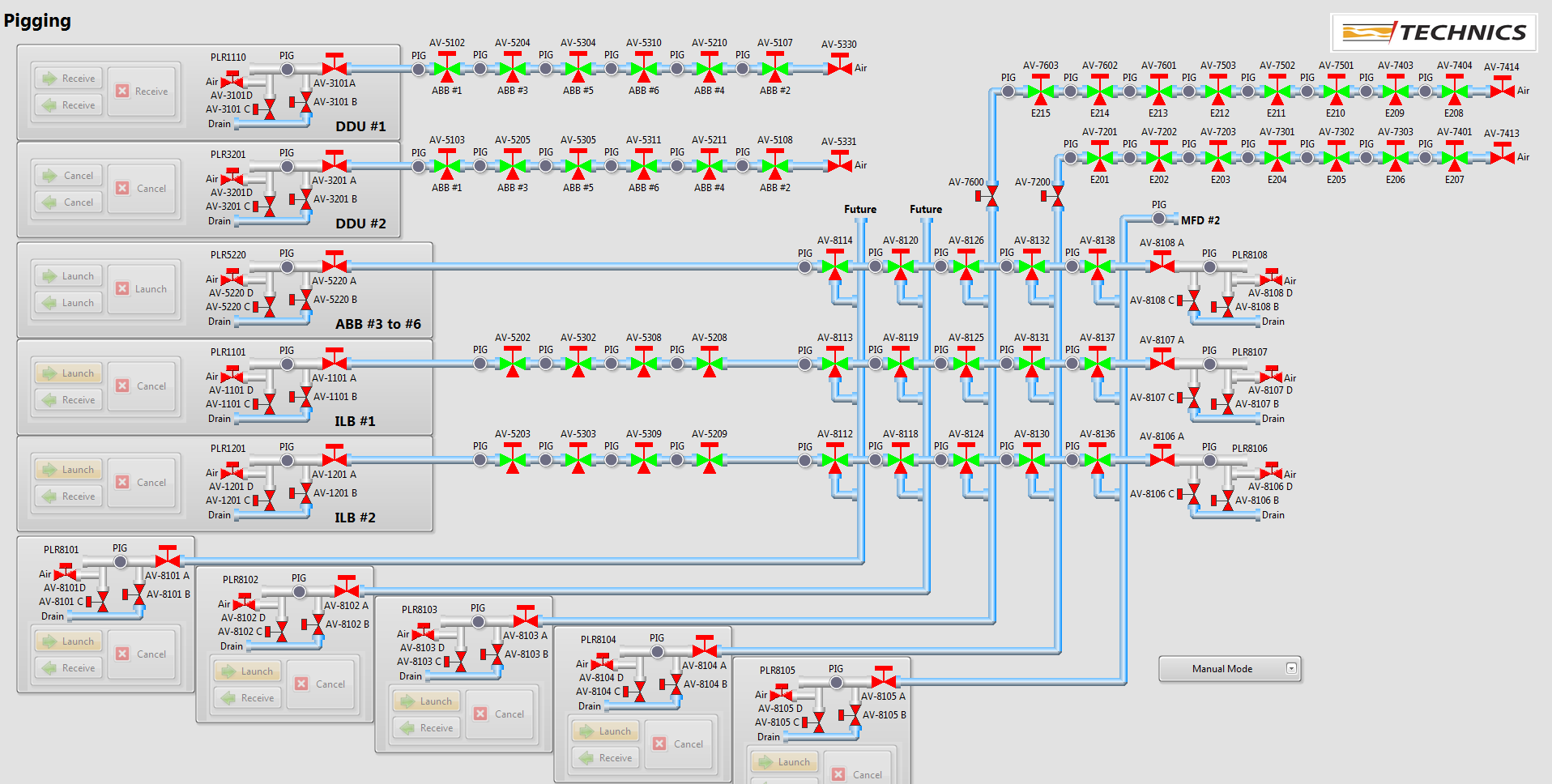

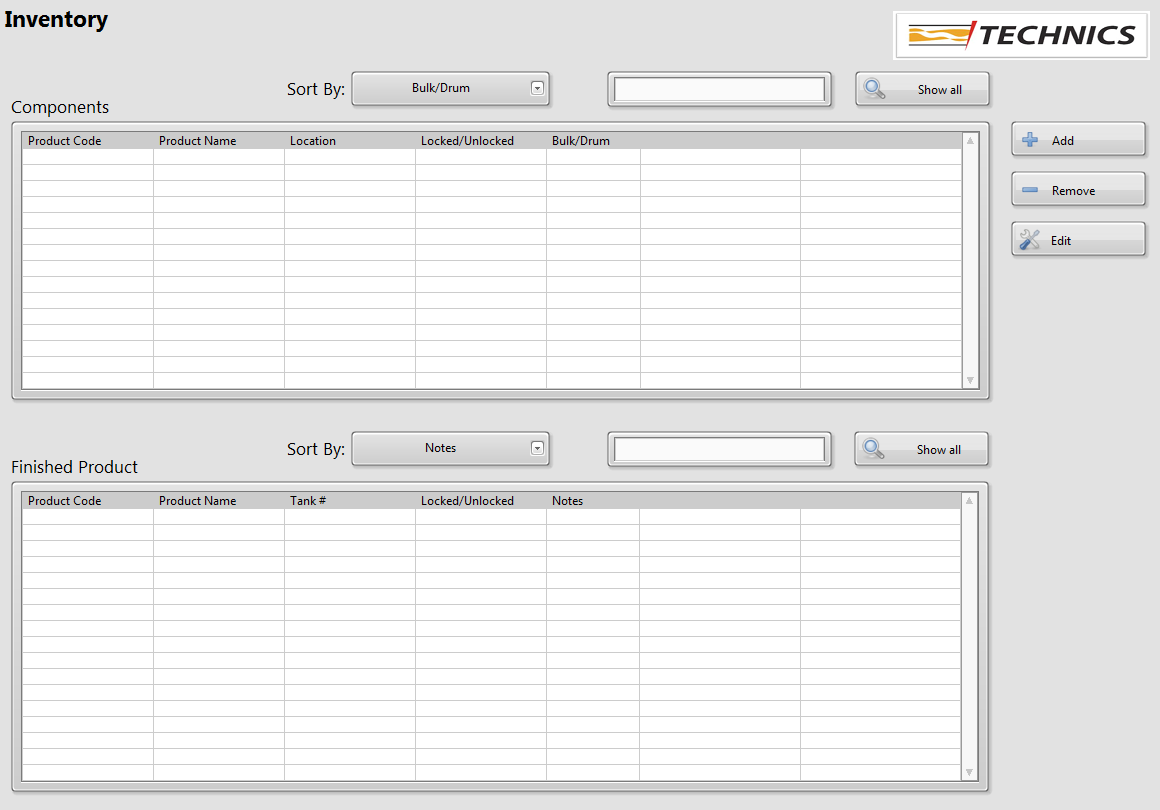

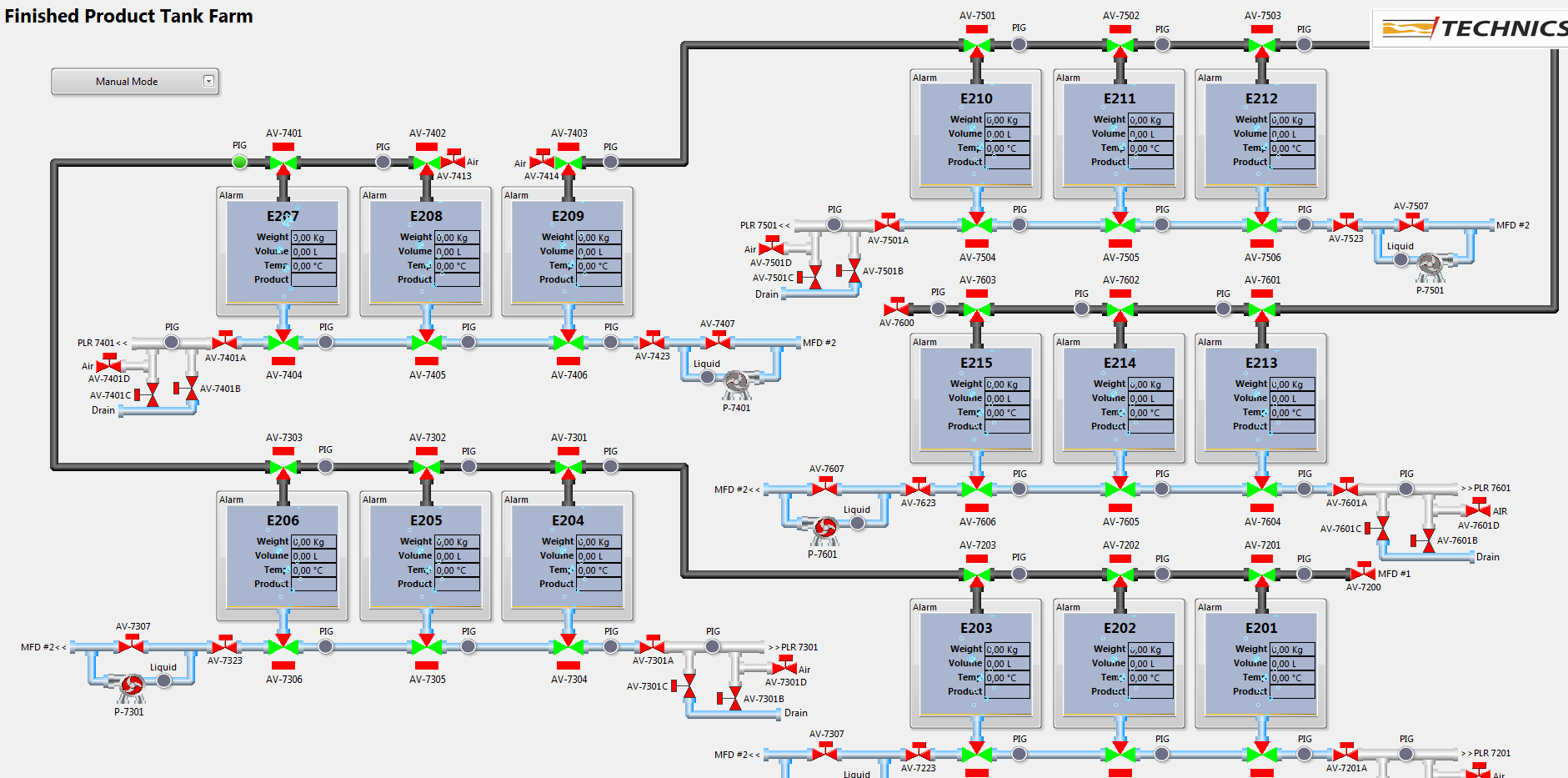

At the order of the American company we developed a program for managing the process of oil mixing at an oil refinery. In order to construct such a system, we developed 20 different windows allowing to manage separate parts of the factory; in this case, when the program works, up to 60 windows can be opened.

The complex manages the factory completely.

The ingredients arriving at the warehouse are measured (weighed) automatically, so the system always contains the latest information about the warehouse stock and the possibility of manufacturing a certain product.

The process engineer is capable of adjusting the recipe (quantity and composition of ingredients, production conditions) and issue production assignments.

The operator controlling the mixing process sees the sequence of orders and the possibility of executing them (based on the information about available stock and vacant tanks). The program blocks the launch of production if an order cannot be executed correctly.

Addition of ingredients and mixing are controlled automatically; information about the progress of production is displayed in real time.

Shipments are also taken into account in the system; thus, information about vacant tanks and warehouse stock of finished products is always true to fact.

It is possible to switch between Russian and English interfaces in the system settings. Moreover, there was implemented a possibility of creating a “language package” containing names of interface elements in a any language, so the interface is multilingual.

Equipment: cRIO controllers and extension racks with discreet and analogue I/O modules, several weigh processors (VP-01), Rigaku and Eraspec analyzers.